compart(@)soyer..co

P.T.H. “COMPART” Zbigniew Dziembowski , PL 44-100 Gliwice , ul. Gen.J.Sowińskiego 5 , (IMN - Budynek C)

Tel: (+48) 322 380 680 | Fax: (+48) 322 380 680 | Email: compart(@)soyer.info.pl

P.T.H. “COMPART” Z.Dziembowski | Tel./Fax: (+48) 322 380 680 | Email: compart (at) soyer.info.pl

Link to: BMS-4 - BMS-8N - BMS-9 - BMS-10N - HesoMatic-9 - BMK-8i - BMK-12i - BMK-12W - BMK-16i - BMH-22i - BMH-30i

THE WORLD OF AUTOMATION

CNC MACHINING CENTRES

We offer a wide range of semi-automated and fully automated CNC machining centres. Here you will find an overview of our portfolio.

KTS-1050 CNC

The KTS-1050 CNC coordinate table in accordance with EU Directive on Machinery 2006/42/EC is a high-quality new development incorporating a solid design with longterm quality and precision. The particularly favourable price/efficiency ratio enables profitable operation even with low and medium-scale manufacture.more

KTS-1550 CNC

The KTS-1550 CNC coordinate table equipped with casing in accordance with EU Directive on Machinery 2006/42/EC is a high- quality new development incorporating a solid design with long-term quality and precision. The particularly favourable price/ efficiency ratio enables profitable operation even with low and medium-scale manufacture.more

PTS-500 NC

The PTS-500 NC stud welding machine allows studs and pins from 3 - 10 mm in diameter and 40 mm in length to be precisely and fully automatically welded in accordance with all known stud welding processes.more

KTS-2550 CNC

The KTS-2550 CNC coordinate table is a high- quality new development incorporating a solid design with long-term quality and precision. The particularly favourable price/ efficiency ratio enables profitable operation even with low and medium-scale manufacture.more

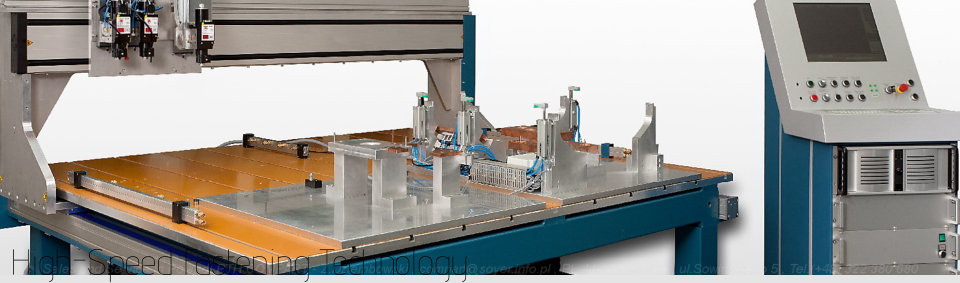

KTS-4000 CNC

High performance and precision – those are the key features of the KTS-4000 CNC stud welding machine. Thanks to the new XXL concept, it is now also possible to manufacture large parts at very economical conditions. A welded and precisely surface- milled machine frame provides maximum stiffness. This helps to ensure high precision and accuracy at all times during continuous operation.more

KTS-1550 W CNC

High performance and precision – those are the key features of the KTS-1550-W CNC stud welding machine. Thanks to the new XXL concept, it is now also possible to manufacture large parts at very economical conditions. A welded and precisely surface- milled machine frame provides maximum stiffness. This helps to ensure high precision and accuracy at all times during continuous operation.more

compart(@)soyer..co

P.T.H.“COMPART” Z.Dziembowski, PL 44-100 Gliwice, ul. Sowińskiego 5

Tel: (+48) 322 380 680 | Fax: (+48) 322 380 680

Email: compart(@)soyer.info.pl

KTS-1050 CNC

The KTS-1050 CNC coordinate table in accordance with EU Directive on Machinery 2006/42/EC is a high-quality new development incorporating a solid design with longterm quality and precision. The particularly favourable price/efficiency ratio enables profitable operation even with low and medium- scale manufacture.more

P.T.H. “COMPART” Z.Dziembowski | Tel: (+48) 322 380 680 |

Fax: (+48) 322 380 680 | Email: compart (at) soyer.info.pl

Link to: BMS-4 - BMS-8N - BMS-9 - BMS-10N - HesoMatic-9 - BMK-

8i - BMK-12i - BMK-12W - BMK-16i - BMH-22i - BMH-30i

THE WORLD OF

AUTOMATION

CNC MACHINING CENTRES

We offer a wide range of semi-automated and fully automated CNC machining centres. Here you will find an overview of our portfolio.PTS-500 NC

The PTS-500 NC stud welding machine allows studs and pins from 3 - 10 mm in diameter and 40 mm in length to be precisely and fully automatically welded in accordance with all known stud welding processes.more

KTS-1550 CNC

The KTS-1550 CNC coordinate table equipped with casing in accordance with EU Directive on Machinery 2006/42/EC is a high- quality new development incorporating a solid design with long-term quality and precision. The particularly favourable price/ efficiency ratio enables profitable operation even with low and medium-scale manufacture.more