compart(@)soyer..co

P.T.H. “COMPART” Zbigniew Dziembowski , PL 44-100 Gliwice , ul. Gen.J.Sowińskiego 5 , (IMN - Budynek C)

Tel: (+48) 322 380 680 | Fax: (+48) 322 380 680 | Email: compart(@)soyer.info.pl

P.T.H. “COMPART” Z.Dziembowski | Tel./Fax: (+48) 322 380 680 | Email: compart (at) soyer.info.pl

Products

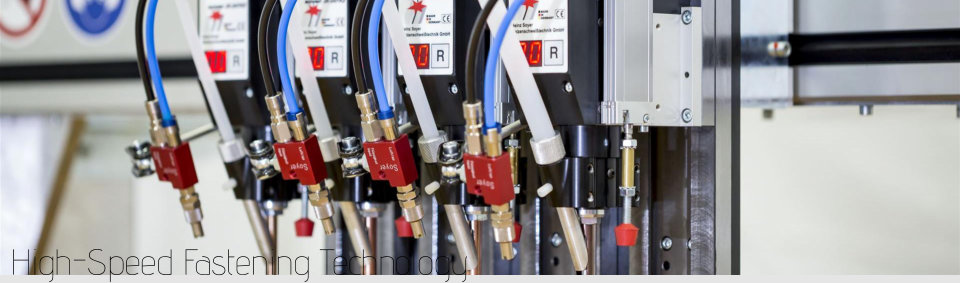

The world of stud welding technology all from one source

Machines, guns, CNC machining centres, studs, welding elements and accessories

Our product range encompasses everything from state-of-the-art portable stud welders to fully automated high-tech CNC machining centres. Here you will find an overview of our bestsellers, classic stud welders and brand-new products.Capacitor Discharge

Capacitor discharge stud welding has been successfully used for many years all over the world. It allows weld studs with a maximum diameter of M12 to be welded. The welding process is executed by discharging the capacitor battery within a fraction of a second from 1 – 3 ms (0.001 – 0.003 sec.) using the welding element’s ignition tip. This procedure has proven invaluable especially in vehicle construction, sheet metal forming and decorative metal design.Drawn Arc Stud Welding

Drawn arc stud welding is a welding procedure for maximum loads. It enables welding of weld fasteners measuring between 6 mm and 25 mm in diameter. The entire welding process is controlled and monitored by an electronic power source. This procedure creates high-quality welded connections and has proven invaluable in steel construction, mechanical engineering, shipbuilding, construction of prefabricated parts made from reinforced concrete, door and window construction, structural and civil engineering, fixture and pipeline construction.SRM Stud Welding Process

The patented SRM stud welding process (patent no.: 10 2004 051 389), in conjunction with the innovative HZ-1 universal weld stud featuring a plane end face and centering tip (patent no.: 10 2006 016 553) enables welds at a sheet thickness to stud diameter ratio of 1:10 instead of 1:4 as previously. In this process, the use of ceramic rings is no longer needed. The numerous advantages delivered by the SRM procedure open up whole new possibilities for application especially in automated stud welding plans and large-scale component production.The World of Automation

High performance and top precision are the fundamental features of all SOYER CNC machining centres. Since 1970 we have been developing and producing customised stud welding machines in all sizes. We provide a truly comprehensive range from semi-automated stud welding machines up to fully automated CNC machining centres in XXXL format.

Special Offer!

PTH ”COMPART” Z.Dziembowski

celebrates 25th anniversary

On this occasion we would like to thank our customers and business partners for the cooperation and the trust you have placed in our company during the past 25 years. We look forward to continuing our mutually beneficial relationship for many years to come.We want to offer the disposable

discount to every company

cooperating with us into heights

of the 10% for one any order

folded to 30.11.2018

With two decades of expertise in the field of high-speed fastening technologies, we offer the entire stud welding product range from a single source . We are aware of our responsibility to market products which function reliably and over the long term, thus optimally meeting customer needs. Product innovations and optimisations are the key factors for success of our company.

Weld Studs

OUR KNOW-HOW =

YOUR ADVANTAGE

Our weld studs are manufactured by SOYER® and are supervised in accordance with the Ü-certification (Ü mark of conformity). The raw materials used in production originate from German and European sources only. The approved quality of our weld studs means we can guarantee the quality of stud welded joints when using SOYER® system components in combination with SOYER® weld fasteners. From your inquiry to the delivery of your merchandise, we are pleased to assist you in the production of optimum welds by providing comprehensive and professional advice.

Link to: BMS-4 - BMS-8N - BMS-9 - BMS-10N - HesoMatic-9 - BMK-8i - BMK-12i - BMK-12W - BMK-16i - BMH-22i - BMH-30i

compart(@)soyer..co

P.T.H.“COMPART” Z.Dziembowski, PL 44-100 Gliwice, ul. Sowińskiego 5

Tel: (+48) 322 380 680 | Fax: (+48) 322 380 680

Email: compart(@)soyer.info.pl

P.T.H. “COMPART” Z.Dziembowski | Tel: (+48) 322 380 680 |

Fax: (+48) 322 380 680 | Email: compart (at) soyer.info.pl

Products

The world of stud welding

technology all from one source

Machines, guns, CNC machining centres,

studs, welding elements and accessories

Our product range encompasses everything from state-of-the-art portable stud welders to fully automated high-tech CNC machining centres. Here you will find an overview of our bestsellers, classic stud welders and brand-new products.Capacitor Discharge

Capacitor discharge stud welding has been successfully used for many years all over the world. It allows weld studs with a maximum diameter of M12 to be welded. The welding process is executed by discharging the capacitor battery within a fraction of a second from 1 – 3 ms (0.001 – 0.003 sec.) using the welding element’s ignition tip. This procedure has proven invaluable especially in vehicle construction, sheet metal forming and decorative metal design.Drawn Arc Stud Welding

Drawn arc stud welding is a welding procedure for maximum loads. It enables welding of weld fasteners measuring between 6 mm and 25 mm in diameter. The entire welding process is controlled and monitored by an electronic power source. This procedure creates high-quality welded connections and has proven invaluable in steel construction, mechanical engineering, shipbuilding, construction of prefabricated parts made from reinforced concrete, door and window construction, structural and civil engineering, fixture and pipeline construction.SRM Stud Welding Process

The patented SRM stud welding process (patent no.: 10 2004 051 389), in conjunction with the innovative HZ-1 universal weld stud featuring a plane end face and centering tip (patent no.: 10 2006 016 553) enables welds at a sheet thickness to stud diameter ratio of 1:10 instead of 1:4 as previously. In this process, the use of ceramic rings is no longer needed. The numerous advantages delivered by the SRM procedure open up whole new possibilities for application especially in automated stud welding plans and large-scale component production.The World of Automation

High performance and top precision are the fundamental features of all SOYER CNC machining centres. Since 1970 we have been developing and producing customised stud welding machines in all sizes. We provide a truly comprehensive range from semi-automated stud welding machines up to fully automated CNC machining centres in XXXL format.

Weld Studs

OUR KNOW-HOW = YOUR

ADVANTAGE

Our weld studs are manufactured by SOYER® and are supervised in accordance with the Ü-certification (Ü mark of conformity). The raw materials used in production originate from German and European sources only. The approved quality of our weld studs means we can guarantee the quality of stud welded joints when using SOYER® system components in combination with SOYER® weld fasteners. From your inquiry to the delivery of your merchandise, we are pleased to assist you in the production of optimum welds by providing comprehensive and professional advice.

Special Offer!

PTH ”COMPART” Z.Dziembowski

celebrates 25th anniversary

On this occasion we would like to thank our customers and business partners for the cooperation and the trust you have placed in our company during the past 25 years. We look forward to continuing our mutually beneficial relationship for many years to come.We want to offer the disposable

discount to every company

cooperating with us into heights of

the 10% for one any order folded to

30.11.2018

With two decades of expertise in the field of high-speed fastening technologies, we offer the entire stud welding product range from a single source . We are aware of our responsibility to market products which function reliably and over the long term, thus optimally meeting customer needs. Product innovations and optimisations are the key factors for success of our company.

Link to: BMS-4 - BMS-8N - BMS-9 - BMS-10N - HesoMatic-9 - BMK-

8i - BMK-12i - BMK-12W - BMK-16i - BMH-22i - BMH-30i