compart(@)soyer..co

P.T.H. “COMPART” Zbigniew Dziembowski , PL 44-100 Gliwice , ul. Gen.J.Sowińskiego 5 , (IMN - Budynek C)

Tel: (+48) 322 380 680 | Fax: (+48) 322 380 680 | Email: compart(@)soyer.info.pl

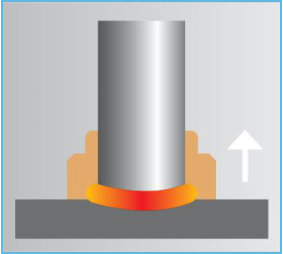

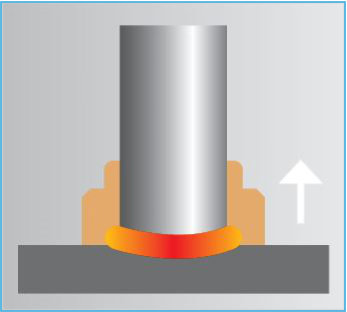

2.

The stud lifts to a pre-set height. The arc is

ignited.

P.T.H. “COMPART” Z.Dziembowski | Tel./Fax: (+48) 322 380 680 | Email: compart (at) soyer.info.pl

Link to: BMS-4 - BMS-8N - BMS-9 - BMS-10N - HesoMatic-9 - BMK-8i - BMK-12i - BMK-12W - BMK-16i - BMH-22i - BMH-30i

DETAILS OF DRAWN ARC STUD WELDING

WITH CERAMIC FERRULE OR SHIELDING GAS

Drawn arc stud welding with shielding gas or with ceramic ferrule is especially suitable when high demands relevant to safety regulations are made on the welding quality. Owing to the increased weld penetration of approx. 1-3 mm, this method is mainly used for workpieces with a minimum thickness of 2 mm. Drawn arc stud welding generates high-quality welded joints. The stud face is completely and perfectly welded to the workpiece. The application of this welding method has proven very successful e.g. in structural steel engineering, mechanical engineering, shipbuilding, building construction and civil engineering, power plant construction, boiler construction, apparatus engineering, insulating engineering, reinforced concrete construction etc. Short-cycle drawn arc stud welding is a variant of drawn arc stud welding. Owing to the low weld penetration of approx. 0.4 mm, this method can even be applied on sheet metals with a minimum thickness of 0.6 mm. When correctly adjusting the welding parameters, this welding process guarantees particularly safe, uniform and reproducible stud welded joints. Test welds have to be carried out when using workpieces with difficult surface characteristics.

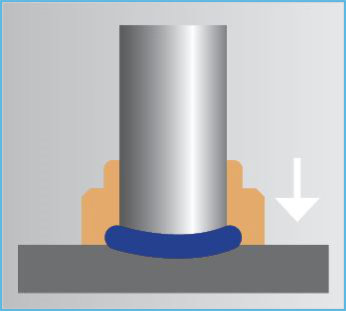

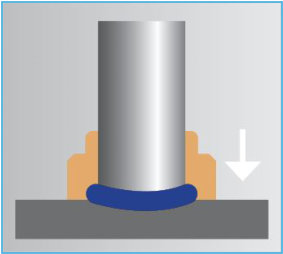

1.

The stud tip is placed into contact with the

workpiece.

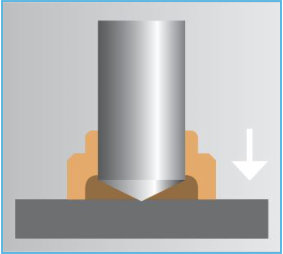

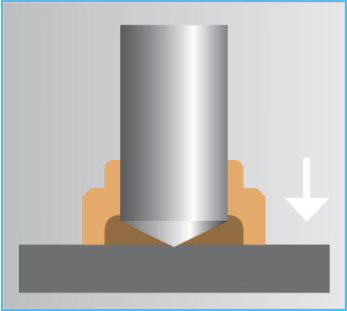

3.

The stud is immersed in the weld pool. The

material solidifies and the stud is

permanently welded.

compart(@)soyer..co

P.T.H.“COMPART” Z.Dziembowski, PL 44-100 Gliwice, ul. Sowińskiego 5

Tel: (+48) 322 380 680 | Fax: (+48) 322 380 680

Email: compart(@)soyer.info.pl

2.

The stud lifts to a pre-set height. The arc is

ignited.

P.T.H. “COMPART” Z.Dziembowski | Tel: (+48) 322 380 680 |

Fax: (+48) 322 380 680 | Email: compart (at) soyer.info.pl

Link to: BMS-4 - BMS-8N - BMS-9 - BMS-10N - HesoMatic-9 - BMK-

8i - BMK-12i - BMK-12W - BMK-16i - BMH-22i - BMH-30i

DETAILS OF DRAWN

ARC STUD WELDING

WITH CERAMIC FERRULE OR

SHIELDING GAS

Drawn arc stud welding with shielding gas or with ceramic ferrule is especially suitable when high demands relevant to safety regulations are made on the welding quality. Owing to the increased weld penetration of approx. 1-3 mm, this method is mainly used for workpieces with a minimum thickness of 2 mm. Drawn arc stud welding generates high-quality welded joints. The stud face is completely and perfectly welded to the workpiece. The application of this welding method has proven very successful e.g. in structural steel engineering, mechanical engineering, shipbuilding, building construction and civil engineering, power plant construction, boiler construction, apparatus engineering, insulating engineering, reinforced concrete construction etc. Short-cycle drawn arc stud welding is a variant of drawn arc stud welding. Owing to the low weld penetration of approx. 0.4 mm, this method can even be applied on sheet metals with a minimum thickness of 0.6 mm. When correctly adjusting the welding parameters, this welding process guarantees particularly safe, uniform and reproducible stud welded joints. Test welds have to be carried out when using workpieces with difficult surface characteristics.

1.

The stud tip is placed into contact with the

workpiece.

3.

The stud is immersed in the weld pool. The

material solidifies and the stud is permanently

welded.