compart(@)soyer..co

P.T.H. “COMPART” Zbigniew Dziembowski , PL 44-100 Gliwice , ul. Gen.J.Sowińskiego 5 , (IMN - Budynek C)

Tel: (+48) 322 380 680 | Fax: (+48) 322 380 680 | Email: compart(@)soyer.info.pl

P.T.H. “COMPART” Z.Dziembowski | Tel./Fax: (+48) 322 380 680 | Email: compart (at) soyer.info.pl

Link to: BMS-4 - BMS-8N - BMS-9 - BMS-10N - HesoMatic-9 - BMK-8i - BMK-12i - BMK-12W - BMK-16i - BMH-22i - BMH-30i

CD STUD WELDING - CAPACITOR DISCHARGE

THE PROVEN TECHNOLOGY

Capacitor discharge stud welding has been successfully used for many years all over the world. It allows weld studs with a maximum diameter of M12 to be welded. When studs are welded to thin sheets (steel, stainless steel, aluminum and brass), the procedure of stud welding with tip ignition will always be the most cost effective process and sometimes the only possible solution. This procedure has proven invaluable especially in electronic industries, food industry, laboratory and medical equipment, vehicle construction, switchboard cabinets, household appliances,sheet metal forming and decorative metal design.

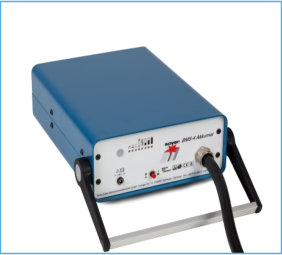

BMS-6 AKKUMAT

Ultra-light equipment for welding studs with battery operation – ideal for insulation pins and cupped head pins.more

BMS-4 AKKUMAT

Ultra-light equipment for welding two M3 studs with battery operation – ideal for heating contractors.more

BMS-9 / BMS-9V

User-friendly state-of-the-art welding device allowing easy selection of welding parameters up to M10.more

BMS-10N / BMS-10NV

Inexpensive all-rounder with welding gun or fully automated stud feed up to M12.more

BMS-8N / BMS-8NV

Our tried and tested CD bestseller with two power levels for welding studs up to M10.more

BMS-10P

Multifunctional stud welder with integrated quality control for semi- and fully automatic welding operation.more

compart(@)soyer..co

P.T.H.“COMPART” Z.Dziembowski, PL 44-100 Gliwice, ul. Sowińskiego 5

Tel: (+48) 322 380 680 | Fax: (+48) 322 380 680

Email: compart(@)soyer.info.pl

BMS-6 AKKUMAT

Ultra-light equipment for welding studs with battery operation – ideal for insulation pins and cupped head pins.more

P.T.H. “COMPART” Z.Dziembowski | Tel: (+48) 322 380 680 |

Fax: (+48) 322 380 680 | Email: compart (at) soyer.info.pl

Link to: BMS-4 - BMS-8N - BMS-9 - BMS-10N - HesoMatic-9 - BMK-

8i - BMK-12i - BMK-12W - BMK-16i - BMH-22i - BMH-30i

CD STUD WELDING -

CAPACITOR

DISCHARGE

THE PROVEN TECHNOLOGY

Capacitor discharge stud welding has been successfully used for many years all over the world. It allows weld studs with a maximum diameter of M12 to be welded. When studs are welded to thin sheets (steel, stainless steel, aluminum and brass), the procedure of stud welding with tip ignition will always be the most cost effective process and sometimes the only possible solution. This procedure has proven invaluable especially in electronic industries, food industry, laboratory and medical equipment, vehicle construction, switchboard cabinets, household appliances,sheet metal forming and decorative metal design.BMS-4 AKKUMAT

Ultra-light equipment for welding two M3 studs with battery operation – ideal for heating contractors.more

BMS-9 / BMS-9V

User-friendly state-of-the-art welding device allowing easy selection of welding parameters up to M10.more

BMS-10N / BMS-10NV

Inexpensive all-rounder with welding gun or fully automated stud feed up to M12.more

BMS-8N / BMS-8NV

Our tried and tested CD bestseller with two power levels for welding studs up to M10.more