compart(@)soyer..co

P.T.H. “COMPART” Zbigniew Dziembowski , PL 44-100 Gliwice , ul. Gen.J.Sowińskiego 5 , (IMN - Budynek C)

Tel: (+48) 322 380 680 | Fax: (+48) 322 380 680 | Email: compart(@)soyer.info.pl

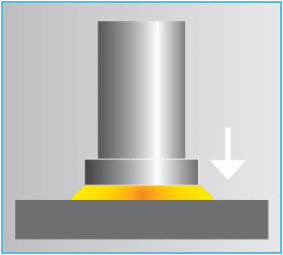

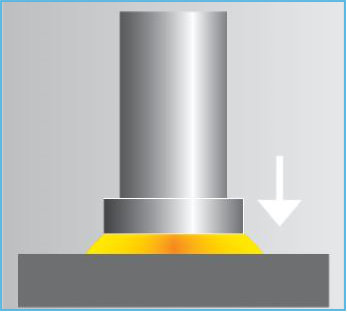

2.

The ignited arc produces a thin melting zone

on the stud and workpiece.

P.T.H. “COMPART” Z.Dziembowski | Tel./Fax: (+48) 322 380 680 | Email: compart (at) soyer.info.pl

Link to: BMS-4 - BMS-8N - BMS-9 - BMS-10N - HesoMatic-9 - BMK-8i - BMK-12i - BMK-12W - BMK-16i - BMH-22i - BMH-30i

DETAILS OF CD STUD WELDING

WITH TIP IGNITION

Capacitor discharge stud welding has been successfully used for many years all over the world. It allows weld studs with a maximum diameter of M12 to be welded. The welding process is executed by discharging the capacitor battery within a fraction of a second from 1 – 3 ms (0.001 – 0.003 sec.) using the welding element’s ignition tip. This procedure has proven invaluable especially in vehicle construction, sheet metal forming and decorative metal design.

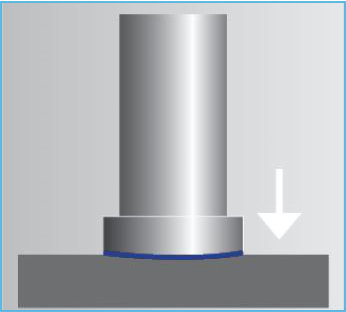

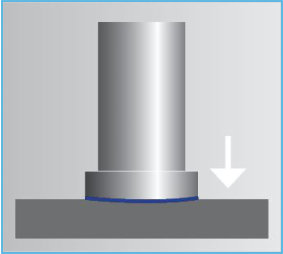

1.

The stud tip comes into contact with the

work-piece. The arc is initiated.

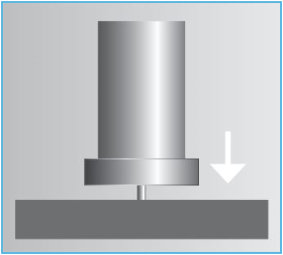

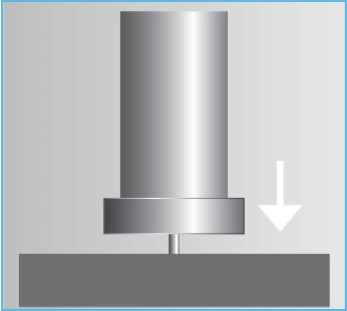

3.

The stud is immersed in the weld pool. The

material solidifies and the stud is welded.

compart(@)soyer..co

P.T.H.“COMPART” Z.Dziembowski, PL 44-100 Gliwice, ul. Sowińskiego 5

Tel: (+48) 322 380 680 | Fax: (+48) 322 380 680

Email: compart(@)soyer.info.pl

2.

The ignited arc produces a thin melting zone on

the stud and workpiece.

P.T.H. “COMPART” Z.Dziembowski | Tel: (+48) 322 380 680 |

Fax: (+48) 322 380 680 | Email: compart (at) soyer.info.pl

Link to: BMS-4 - BMS-8N - BMS-9 - BMS-10N - HesoMatic-9 - BMK-

8i - BMK-12i - BMK-12W - BMK-16i - BMH-22i - BMH-30i

DETAILS OF CD STUD

WELDING

WITH TIP IGNITION

Capacitor discharge stud welding has been successfully used for many years all over the world. It allows weld studs with a maximum diameter of M12 to be welded. The welding process is executed by discharging the capacitor battery within a fraction of a second from 1 – 3 ms (0.001 – 0.003 sec.) using the welding element’s ignition tip. This procedure has proven invaluable especially in vehicle construction, sheet metal forming and decorative metal design.

1.

The stud tip comes into contact with the work-

piece. The arc is initiated.

3.

The stud is immersed in the weld pool. The

material solidifies and the stud is welded.